Description

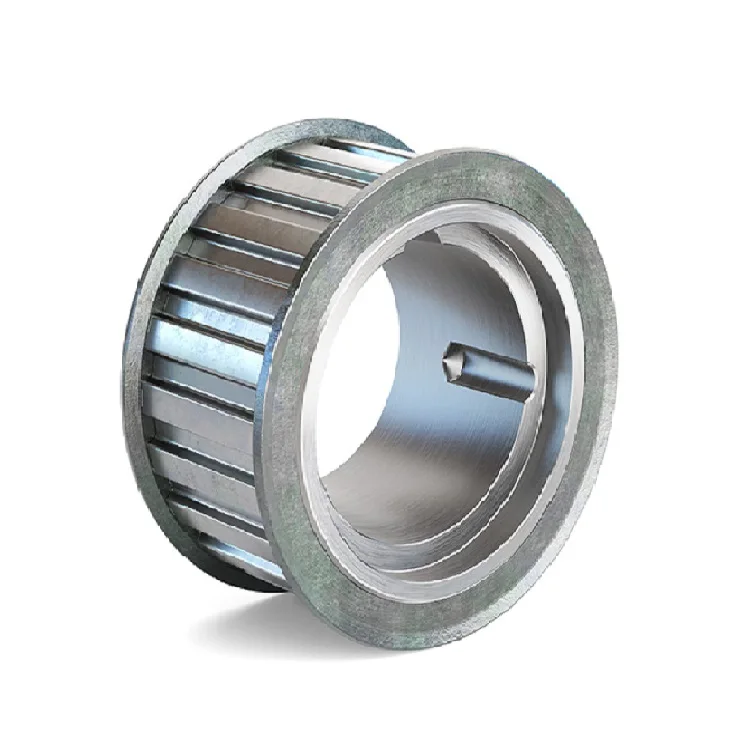

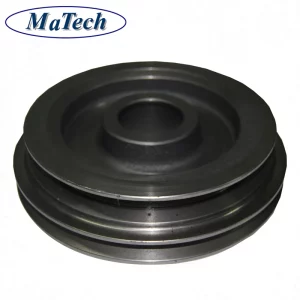

China Supplier Custom Lost Wax Casting Method Of Casting Steel Pulley

Model Number: OEM Customized

Item: China Supplier Custom Lost Wax Casting Method Of Casting Steel Pulley

Material: G35, G45, WCB, WCA, WCC, ISO 340-550, etc. As customer request

Manufacturing Process: Investment casting, option Lost wax casting

Casting Tolerance: CT4-8 for lost wax casting steel pulley

Machining Process: CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling etc.

Machining Tolearnce: Up to IT7, Ra 0.8~3.2 , according to customer requirement

Surface Treatment: Surface Passivatin, Polish. As customer requests.

Package: Multilayer wood box with big plastic bag inside.

Lead Time: about 55 days for lost wax casting steel pulley

Service: Supply lost wax casting steel pulley

Product Introduction

The Custom Lost Wax Casting Method of Casting Steel Pulley is a product of high precision and superior quality. The key features of this product include:

- Durable Material: Made from G35, G45, WCB, WCA, WCC, ISO 340-550, etc

- High Precision: Casting Tolerance of CT4-8, Machining Tolerance up to IT7, Ra 0.8~3.2

- Excellent Surface Treatment: Including Surface Passivation and Polish

- Customizable: Specifications and features can be customized as per customer request

- Efficient Service: We ensure a lead time of about 55 days for lost wax casting steel pulley

Product Usage

The Lost Wax Casting Steel Pulley can be used in a variety of applications. Let’s delve into its uses:

- Vehicle Manufacturing: This product can be used in the creation of various vehicle parts.

- Agricultural Machinery: The steel pulley can be applied in agriculture machinery for efficient operations.

- Construction Equipment: It’s also ideal for use in construction machines due to its durability and strength.

- Transportation Equipment: The steel pulley is also useful in the manufacture of various transportation equipment.

- Valve and Pump Systems: It finds usage in valve and pump systems as well.

Product Maintenance

Maintaining the Lost Wax Casting Steel Pulley is essential for its longevity. Here are some tips:

- Regular Inspection and Repair: Frequent checks can help identify and rectify any issues early.

- Regular Cleaning: Cleaning the pulley helps maintain its efficiency and prevent build-up.

- Lubrication: Proper lubrication ensures smooth operation and prevents wear and tear.

- Regular Replacement: Depending on usage intensity, consider regular replacement to maintain optimal performance.

Explore our high-quality Lost Wax Casting Steel Pulley and enjoy the benefits of durability and precision. Place your order now!

About Our Company

We are a company specializing in the production of mechanical transmission parts. The company mainly produces and sells European standard taper sleeve pulley, TB type taper sleeve pulley, American standard taper sleeve pulley, QD type taper sleeve, taper sleeve type multi-wedge pulley, national standard pulley, fan shaft, transmission parts, etc. Annual output of more than 500,000 pulley, more than 200,000 conical sleeve. The annual output value is more than 30 million. We can process all kinds of mechanical parts according to the needs of customers, including non-standard parts. The parts have a short processing cycle, and the products are sold all over the world and overseas. The company’s flexible management system, perfect quality management system, sophisticated processing equipment, advanced and reasonable production technology, strict inspection of each process, to ensure that the quality of each product is in line with the requirements of the drawings, the advanced quality products to the market. Our products are reasonably priced and we provide one-stop service for our customers. Welcome new and old customers to inquire and business negotiations.

Frequently Asked Questions

- What materials are used to make the Lost Wax Casting Steel Pulley? The pulley is made from G35, G45, WCB, WCA, WCC, ISO 340-550, etc.

- What is the casting tolerance of the Lost Wax Casting Steel Pulley? The casting tolerance is CT4-8 for the lost wax casting steel pulley.

- What is the lead time for the Lost Wax Casting Steel Pulley? The lead time is about 55 days for the lost wax casting steel pulley.