Description

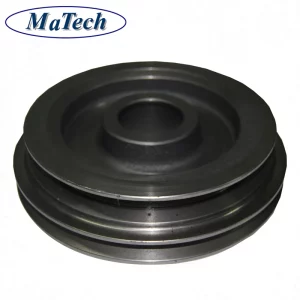

The Precision Casting Custom Made Transmission Steel Alloy Pulley Wheel is an exceptional product designed to cater to varied customer requests. Made from materials like G35, G45, WCB, WCA, WCC, and ISO 340-550, it is manufactured using the Investment casting process with an optional Lost wax casting process. With a Casting Tolerance of CT4-8, the steel alloy pulley wheel is machined through CNC Machining/ Lathing/ Milling/ Turning/ Boring/ Drilling. The Machining Tolerance is up to IT7, Ra 0.8~3.2, as per the customer requirement. The surface treatment includes Surface Passivation and Polishing. The product comes in a multilayer wood box with a big plastic bag inside and has a lead time of about 55 days.

Product Highlights

The Precision Casting Custom Made Transmission Steel Alloy Pulley Wheel is a standout product due to its:

- Customizable nature that caters to specific customer requests

- Use of diverse materials like G35, G45, WCB, WCA, WCC, and ISO 340-550

- Highly precise manufacturing and casting processes

- Superior machining tolerance up to IT7, Ra 0.8~3.2

- Quality surface treatment for enhanced durability

We take pride in our ability to manufacture these products that are not only of high quality but also cater to the specific needs of our customers.

Product Application

This precision-casted alloy pulley wheel can be used in various applications. It’s perfect for:

- Vehicle parts

- Agriculture machine parts

- Construction Machine parts

- Transportation equipment parts

- Valve and Pump system parts

Each of these applications benefits from the product’s high durability, precision engineering, and customizable nature.

Product Maintenance

To keep the Precision Casting Custom Made Transmission Steel Alloy Pulley Wheel in optimal condition, follow these maintenance tips:

- Regular Inspection and Repair: Check for any visible damages or wear and tear.

- Regular Cleaning: Clean the product regularly to prevent dust accumulation.

- Lubrication: Keep the wheel lubricated to ensure smooth operation.

- Replacement: Replace the wheel when necessary to maintain efficiency.

We encourage you to explore this exceptional product and make a purchase. It’s a valuable addition to your equipment that promises high performance and durability.

About Us

We are a company specializing in the production of mechanical transmission parts. We produce and sell various types of pulleys, fan shafts, transmission parts, etc. Our products are of high quality, reasonably priced, and we provide one-stop service for our customers. We welcome new and old customers to inquire and business negotiations.

FAQ

- What is the lead time for the Precision Casting Custom Made Transmission Steel Alloy Pulley Wheel?

The lead time is approximately 55 days.

- What is the manufacturing process used for this product?

We use the Investment casting process with an optional Lost wax casting process.

- What materials are used in the production of the Precision Casting Custom Made Transmission Steel Alloy Pulley Wheel?

We use materials like G35, G45, WCB, WCA, WCC, and ISO 340-550.